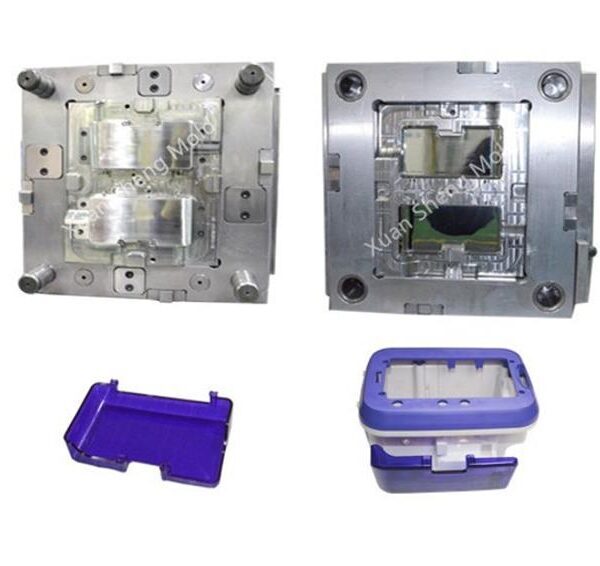

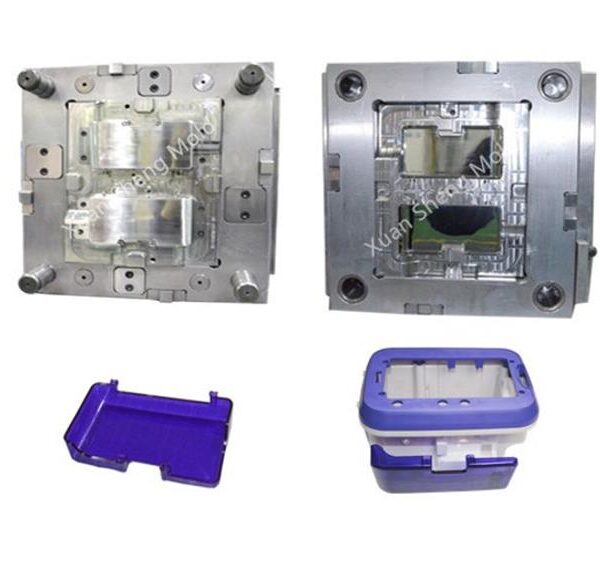

Medical nutrition pump injection mold

| Product Name | Nutrition pump |

| Cavity | Single/Multi |

| Runner | Hot/cold |

| Mold material | P20,718,718H,NAK80,S136…… |

| product size | customize |

| product material | ABS,PC,PP,PA6,PA6+GF30…… |

- Description

- Inquiry

Medical mould-Medical nutrition pump injection mold.Moreover ,one stop solution provider for help plastic injection molding as best partner.

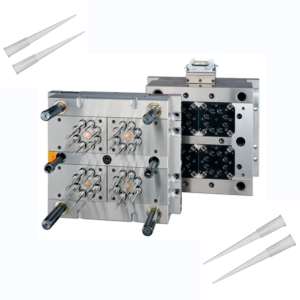

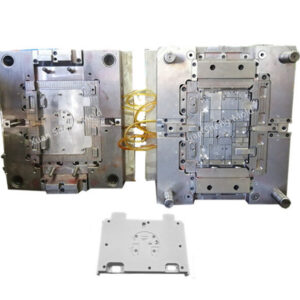

Our company has made many medical molds for mediacal devices.This is the medical nutrition pump.The plastic parts of this machine are injection-molded by 14 sets of molds.

The appearance of medical device products is mostly dermatoglyph, and the requirements for appearance are very high. There should be no scratches and assembly dislocation.

There are probably several methods for processing the texture of the mold: 1. Sandblasting; 2. Chemical corrosion; 3. Electro-discharge machining.

However, most medical device product shells have fine lines on the dermatoglyph surface.

Of course, in addition to the exterior parts, there are many small parts inside, and the assembly size of each part is very important.

A major feature of medical device molds is that there are more mold sliders and inclined top structures.

Looking foward to providing you with better service.

| Certification | ISO 9001 & ISO 13485 & IATF 16949 |

| Product Design | R&D engineer team free to discuss with expert’s concept suggestions |

| 3D Sample | Available |

| Mold Design | Professional analysis from product model design to production by molding |

| Advantage |

|

Business Terms:

- Please share us your detail CAD or 3D drawns, or samples

- All products will produced and delivered under the approved drawings by clients.

- We keep confidential the product information of our customers.

- The intellectual property rights of product belongs to client and have no relationship with us.

- Trade Terms: EXW, FOB, CIF or required.

- Payment terms: 50% remittance by T/T in advance, balance 50% before shipment.

- T0 time: From deposit arrived in our account, to clients confirm the drawn design.

- T1 time: After customer confirmed 3D mold drawing, till we arrange courier samples to clients for confirmation.

Welcome visiting us, during the special time, We can also show our factory by video at any time.