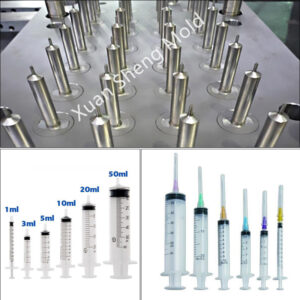

Medical consumables precision injection molding & mold-URINE CUP

| Product Name | Urine container |

| Cavity | multi |

| Runner | Hot |

| Mold material | H13,S136,1.2344,1.2083,1.1045 |

| Tube size | 50ml,60ml,80ml,100ml,120ml |

| Tube material | PP |

- Description

- Inquiry

Medical injection molding companies– Provide one-stop services for plastic product design housing, mold manufacturing & tooling injection as OEM mass production

The urine container is made of two parts ,the container and the cup.

Our company has made two parts mold already.It is for 120ml urine container.

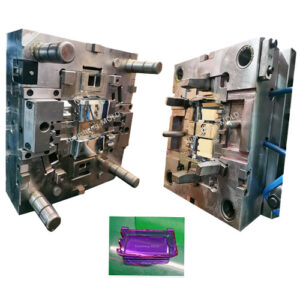

The urine container mold has 6 cavity and its mold material is S136.The mold has hot runner system and its brand is YUDO.The feeding gate is needle point.There are 6 needle points.The mold size is 400*850*580mm,and its weight is 948KG. It is suitable for production on a 280T injection molding machine.

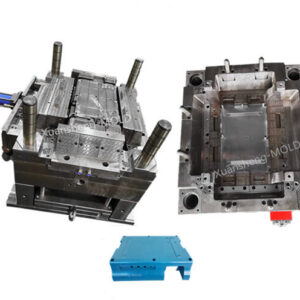

The urine cup mold has 6 cavity and its mold material is S136 too.The mold also has hot runner system,but it is only three open points.The product adopts the submerged glue method of transferring the hot runner to the cold runner.The mold size is 400*500*530 and its weight is 612kg.It is suitable for production on a 200T injection molding machine.The mold has the unthreaded mechanism of the cylinder actuating the motor.

Welcome you inquiry.

Looking foward to providing you with better service.

| Certification | ISO 9001 & ISO 13485 & IATF 16949 |

| Product Design | R&D engineer team free to discuss with expert’s concept suggestions |

| 3D Sample | Available |

| Mold Design | Professional analysis from product model design to production by molding |

| Advantage |

|

Business Terms:

- Please share us your detail CAD or 3D drawns, or samples

- All products will produced and delivered under the approved drawings by clients.

- We keep confidential the product information of our customers.

- The intellectual property rights of product belongs to client and have no relationship with us.

- Trade Terms: EXW, FOB, CIF or required.

- Payment terms: 50% remittance by T/T in advance, balance 50% before shipment.

- T0 time: From deposit arrived in our account, to clients confirm the drawn design.

- T1 time: After customer confirmed 3D mold drawing, till we arrange courier samples to clients for confirmation.

Welcome visiting us, during the special time, We can also show our factory by video at any time.