Precision plastic injection molding & injection molds for sale -Blood collection test tube

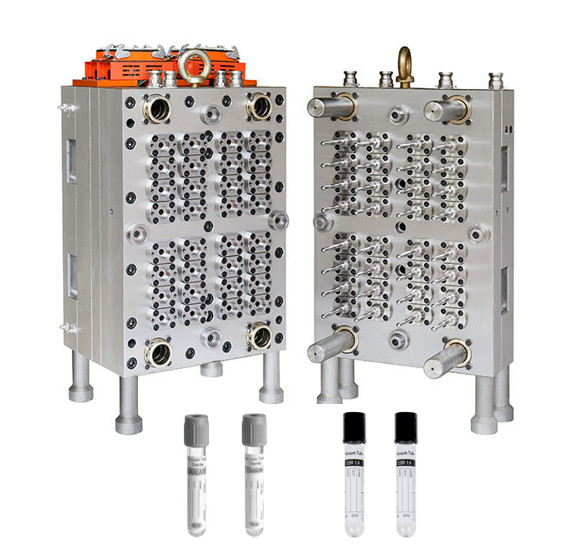

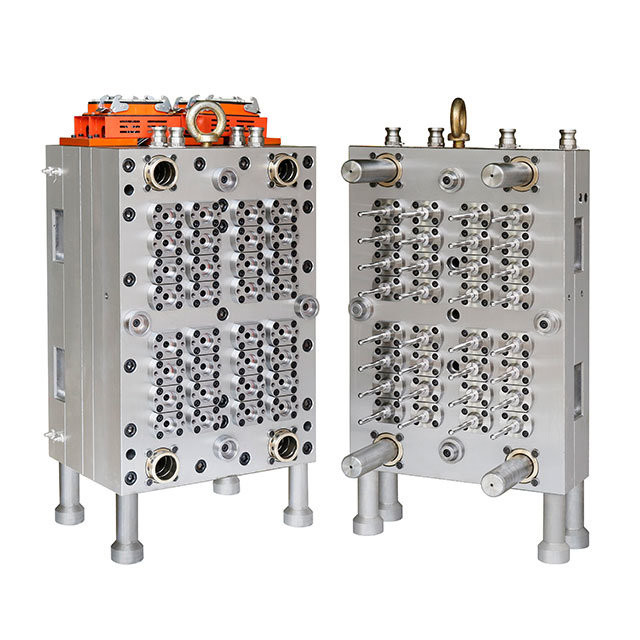

| Product Name | Medical blood collection test tube mold |

| Cavity | 32/64 |

| Runner | Husky valve gate hot runner system |

| Mold material | Mold base material : 420 stainless steel Mold cavity material: Austrian Bohler mold steel |

| Tube size | 13*75,13*100,16*100 |

| Tube material | PET |

| Cycle time | 10s or so |

- Description

- Inquiry

Blood collection test tube mold -Provide different solutions according to customer requirements, from product optimization, mold design to mass production.

Blood collection tube injection molding requires an electric injection molding machine or an oil-electric hybrid injection molding machine is required, and the production in a 100K clean workshop. To ensure productivity and a clean environment.

There are about 3 kinds of materials for BCT: PET, PP, and glass. The cost of glass material is too high. Compared with the BCT made of PP material, PET material has a higher vacuum rate and a higher water retention rate. Therefore, most of the BCT made of PET is used in the market.

BCT has very high requirements for dimension and concentricity. Otherwise, it will have a great impact on the assembly of the product and the volume value of the product.

The core and cavity sides of the BCT molds are made of movable inserts so that it is convenient to adjust the product’s dimension; each cavity has its own cooling water circuit so that the molding cycle is shorter.

PET tube material has poor fluidity, so a good quality HUSKY valve gate HRS is necessary. To ensure better temperature control balance.

Hope to provide you with better service.

| Certification | ISO 9001 & ISO 13485 & IATF 16949 |

| Product Design | R&D engineer team free to discuss with expert’s concept suggestions |

| 3D Sample | Available |

| Mold Design | Professional analysis from product model design to production by molding |

| Advantage |

|

Business Terms:

- Please share us your detail CAD or 3D drawns, or samples

- All products will produced and delivered under the approved drawings by clients.

- We keep confidential the product information of our customers.

- The intellectual property rights of product belongs to client and have no relationship with us.

- Trade Terms: EXW, FOB, CIF or required.

- Payment terms: 50% remittance by T/T in advance, balance 50% before shipment.

- T0 time: From deposit arrived in our account, to clients confirm the drawn design.

- T1 time: After customer confirmed 3D mold drawing, till we arrange courier samples to clients for confirmation.

Welcome visiting us, during the special time, We can also show our factory by video at any time.